Sealcoating is a pavement maintenance technique utilized by many commercial and industrial facilities, HOA communities as well as city, county, and state agencies to extend the life of their pavement surfaces. In fact, it is one of the most important elements of a pavement maintenance plan in relation to how it protects surfaces against gasoline, oil, salt, water, and ultraviolet rays – all of which create havoc for asphalt surfaces.

Benefits of Sealcoating Asphalt Surfaces

We recommend that our customers sealcoat their asphalt surfaces for many reasons.

It Reduces Oxidation of the Pavement

Oxidation is the graying in the color of asphalt pavement and is a sure-fire sign of fatigue, aging, and general surface deterioration. When unprotected pavement becomes oxidized the aggregate will begin to ravel from the surface making the pavement rough. Once the surface becomes brittle, cracks develop, and the pavement deteriorates.

Due to the viscosity of the sealcoat material, it can easily flow into all surface voids within the pavement. Having the extra layer of protection helps to reduce exposure to oxygen, UV rays, and reduces the depth to which oil or gas can penetrate the pavement.

It Provides Waterproofing

One of the major benefits of a sealcoat is that it acts as a barrier between water and the pavement below. Without it, water can permeate more freely resulting in freeze/thaw expansion and contraction of the pavement. Water that accumulates in open pavement structures is a major cause of pavement damage.

It’s Cost-Effective

Compared to a mill & fill or complete pavement reconstruction which can cost several dollars per square foot, asphalt sealcoating typically costs only pennies per square foot and is an affordable way to minimize daily wear and tear of traffic on your parking lot or roadway.

Please keep in mind that crude oil prices often dictate the price of sealcoat materials, so the fluctuation in pricing does occur season-to-season and even month-to-month.

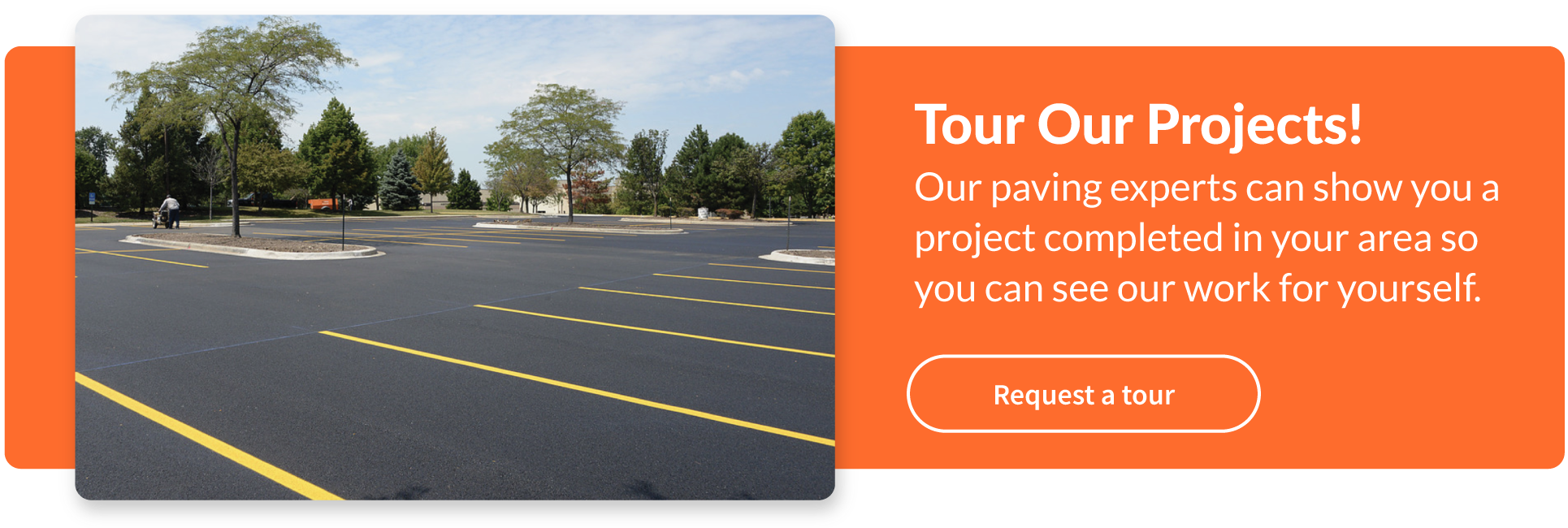

It Improves Aesthetics

In addition to its practicality, sealcoating also enhances the appearance of pavement by giving it an attractive slate-black color finish. Many who utilize sealcoating note how it helps to project a positive image of the company, facility, or residential complex.

How Sealcoating Is Applied

Sealcoat materials consist of an asphalt cement (AC) mixed with water, emulsifying agents, or additives. Many producers add a rubber-like polymer into the AC as a way of adding extra flexibility and durability to the sealcoat.

Due to the intricate formulation of the sealcoat material, it is imperative that sealcoating only be performed under the proper weather conditions. Recommended air and pavement temperature should be at least 55 degrees Fahrenheit and rising during sealer application and for 8 hours afterward.

Once all weather conditions are met, and prior to pavement sealing, any structural failures or cracks on the pavement must be repaired. All potholes must be removed and replaced, cracks must be cleaned and filled, and oil spots cleaned or primed.

At that point, sealcoating is ready to commence. Traditionally applied by a contractor via an asphalt spray machine, sealcoat application rates range between 50-65 square feet per gallon.

Once the sealcoat material is applied, traffic should be kept off the newly sealed surface for at least 18 to 36 hours to allow the sealcoat material to cure. For the days and week following a sealcoat application, it is imperative to refrain from using sprinklers (or any water) near the area.

When Do You Need Sealcoating?

A rule of thumb is to start evaluating maintenance techniques like sealcoating 1 year after the new pavement is placed.

We were one of the first companies to offer commercial sealcoating services in the Chicagoland area in the 1960s! Our highly-experienced team can help you protect and enhance the look of your asphalt pavement. Get in touch with us for a quote today.